2L-100L Stainless Steel Reactor

2L-100L Stainless Steel Reactor

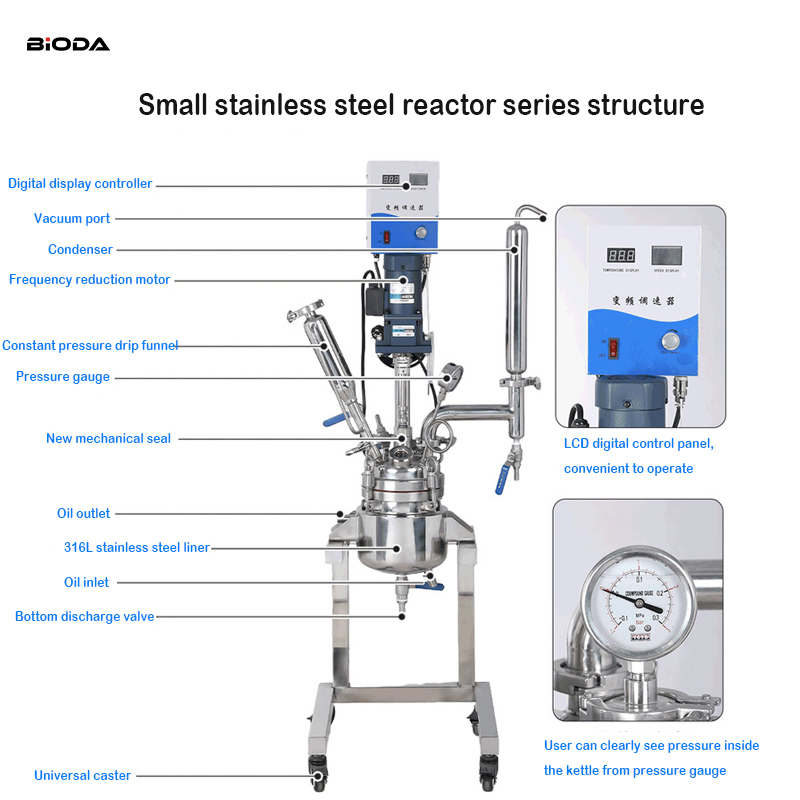

The double-layer stainless steel reactor is designed with double-layer stainless steel. The inner layer can be placed in the reaction solvent for stirring reaction, and the interlayer can be connected to different cold and heat sources (refrigerated liquid, hot water or hot oil) for circulating heating or cooling reaction. Under the set constant temperature conditions, in the closed stainless steel reactor, stirring reaction can be carried out under normal pressure or negative pressure conditions according to the use requirements, and the reaction solution can be refluxed and distilled. It is an ideal pilot and production equipment for modern fine chemical plants, biopharmaceuticals and new material synthesis.

Features:

1. Frequency conversion speed regulation, AC induction motor. Constant speed, no brushes, no sparks, safe and stable, can work continuously.

2. The whole set of instruments is made of SUS316L/SUS304 stainless steel, with good chemical and physical properties.

3. The interlayer interface is passed through hot oil for circulation, which can be used for heating reaction, and the freezing liquid can be passed through for low-temperature reaction.

4. It can react at room temperature, and tap water can quickly take away the reaction heat.

5. The lower discharge port uses a stainless steel ball valve, there is no dead corner in the container, and it can be disassembled to facilitate the discharge of solid materials.

6. The multi-port reactor cover, the extra-large port design is easy to clean, and the standard port socket can be selected to assemble the reflux and distillation synthesis device.

Technical parameters:

Small stainless steel reactor parameters | ||||

Model | BSF-2L | BSF-3L | BSF-5L | BSF-10L |

Motor power (W) | 120(1:3) | 200(1:3) | ||

Dimensions (mm) | 450*450*1410 | 450*450*1450 | 450*450*1500 | 480*480*1560 |

Number of kettle cover openings | 7 ports | 8 ports | ||

Temperature measuring hole | 50.5 chuck/φ8 temperature measuring tube | |||

Drip hole | 50.5 chuck/500ml constant pressure funnel | |||

Return port | 50.5 Chuck | 20~110 | ||

Scraper sight glass (φ) | 32 | 51 | ||

Sight glass (middle) | 32 | |||

Exhaust | 2-way exhaust valve | |||

Stirring | SUS316L propeller mixer φ12 | SUS316Lφ20 | ||

High and low temperature resistance (℃) | -120~260 | |||

Stainless steel thickness (φ) | 3 | |||

Discharge valve diameter (φ) | 20 | 35 | ||

Medium and large stainless steel reactor parameters | |||||||

Model | BSF-20L | BSF-30L | BSF-50L | BSF-100L | |||

Motor power (W) | 200(1:3) | ||||||

Dimensions (mm) | 500*500*1850 | 530*530*1900 | 580*580*2100 | 1050*690*2350 | |||

Number of kettle cover openings | 8 ports | ||||||

Temperature measuring hole | 50.5 chuck/φ10 temperature measuring tube | 50.5 chuck/φ12 temperature measuring tube | |||||

Drip hole | 50.5 chuck/1000ml constant pressure funnel | 50.5 chuck/2000ml constant pressure funnel | |||||

Return port | 50.5 chuck/500ml elbow | 50.5 chuck/φ38 | |||||

Scraper sight glass (φ) | 51 | 89 | |||||

Sight glass (φ) | 51 | 1 | |||||

Feeding port (φ) | / | 89 | |||||

Pressure gauge | 50.5 chuck/± integrated pressure gauge | ||||||

Exhaust | 2-way exhaust valve | ||||||

Stirring | SUS316L propeller mixer φ20 | ||||||

High and low temperature resistance (℃) | -120~260 | ||||||

Stainless steel thickness (φ) | 3 | 4 | |||||

Discharge valve diameter (φ) | 35 | ||||||

Product details:

没有了

Next